The role of crane outrigger safety for heavy machinery

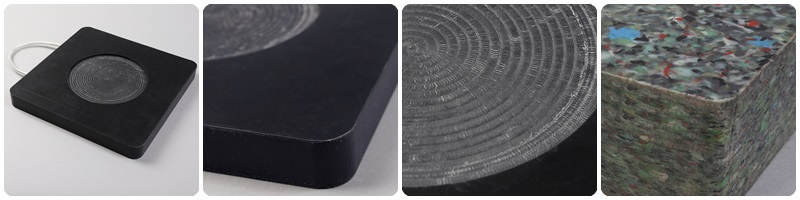

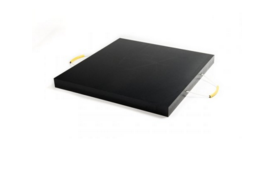

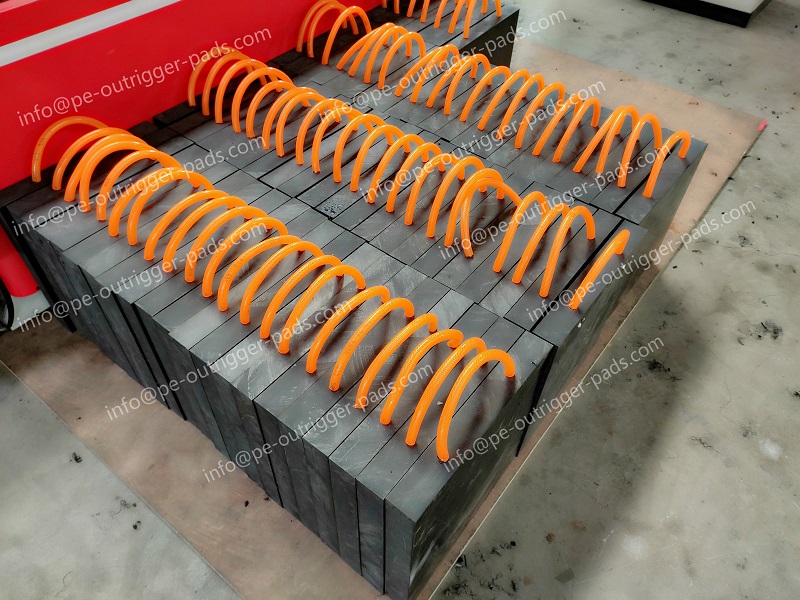

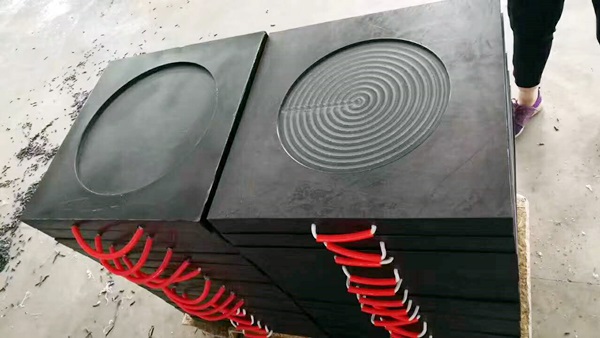

The crane outrigger safety can effectively disperse the construction machine’s own weight and lifting weight to the outrigger pads, which can ensure the normal operation of the ground environment of the construction machine. When the working environment on the ground is uncertain, the use of outriggers can effectively prevent severe accidents.

Crane outrigger safety often act on the legs of engineering machinery and play a supporting role. They have high strength and stiffness, provide more stable support for mechanical engineering work, and are an indispensable good helper for mechanical engineering. What should we pay attention to when using support pads?

- To clean up the work site, you should work on solid ground to increase the surface area.

- If the machine must be operated on non-horizontal surfaces, such as on pits and slopes, sufficient space and support area should be reserved for people to escape. When the legs are extended or retracted, the legs in the danger zone have a range of rotation, and sufficient support areas can prevent tilting.

- In addition, try to avoid changes in ground conditions caused by rain, snow or other water sources; also pay attention to avoid ground subsidence on support legs. This will lead to accidents caused by imbalance of the working surface.