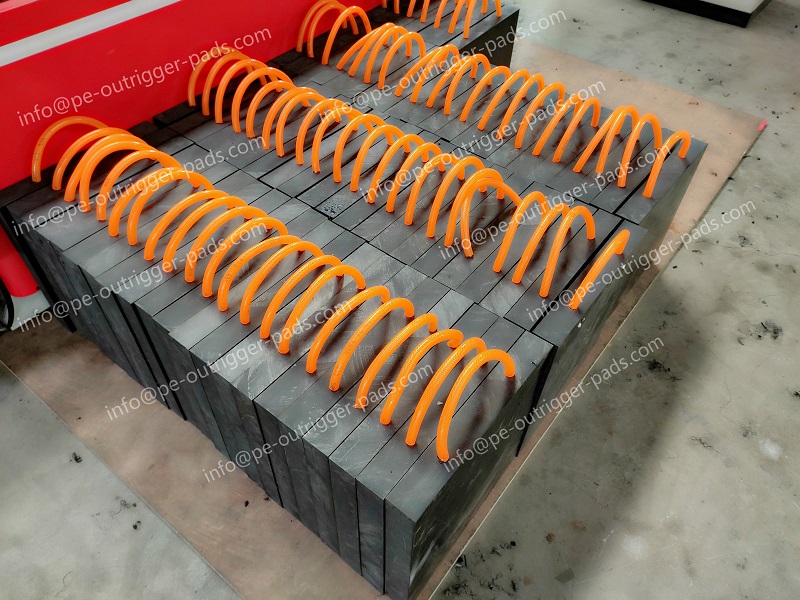

Durable Polyethylene Heavy Duty Crane Outrigger Pad Manufacturer

The English of product is: uhmwpe heavy duty crane outrigger pad, which is the highest quality polyethylene available in harsh working environments and multiple uses. The applicability is very good under many difficult application conditions.

Ultra-high molecular weight heavy duty outrigger pad is a unique characteristic of this polymer, which has a molecular weight of 3 to 6 million, while high-density polyethylene resin is only 300,000 to 500,000. This difference is to ensure that the ultra-high molecular weight polyethylene has sufficient strength to achieve the wear resistance and impact resistance that other lower polymer products cannot have.

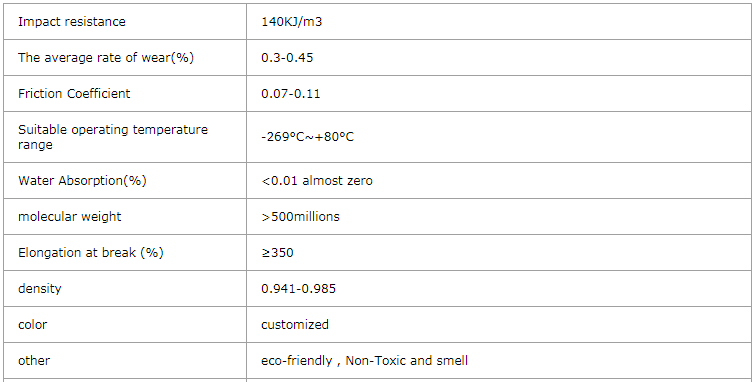

Features of UHMWPE polyethylene outrigger pad:

Wear-resistant, impact-resistant, self-lubricating, chemical resistant, low temperature resistant, hygienic, non-toxic, non-sticky, low water absorption, low density, high tensile strength, aging resistance, flame retardant.