High quality crane outrigger cribbing

After years of development, Tangyin Xinxing has a strong technical force, capable and high-quality team, advanced production system and scientific management system, advanced production equipment, sound quality inspection mechanism and perfect after-sales service. In order to ensure the quality of the crane outrigger cribbing, our quality and service attitude have won praise from our customers.

Our company implements the scientific development concept, introduces advanced production technology and management concepts, and pursues excellence is our direction. The ultra-high molecular weight polyethylene crane outrigger cribbing is reliable in quality, and the pre-sales and after-sales service system is perfect, which makes our products have a high reputation in the similar products of engineering plastics industry. I take the customer’s needs as the demand and the customer’s goal as the goal. Welcome customers to join hands with us.

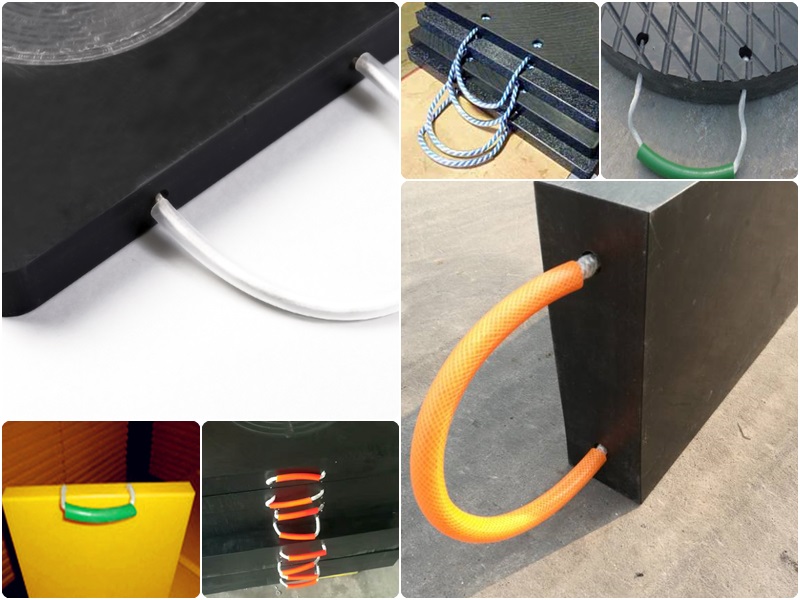

Crane outrigger cribbing characteristics

Light weight, which is 1/7 of the weight of steel.

Withstand loads up to 20 Mpa.

Maintain its physical properties to -80 ° C.

Will not corrode, rot or rust.

High impact resistance and wear resistance.

Can withstand compressive loads exceeding 450T.

The physical properties of the UHMW leg pads do not decompose over time.

Does not absorb moisture, does not swell over time due to exposure to the outdoors.

Will not lose impact over time.

Chemical resistant.

It is safer to use in the field than other wooden mats.

The quality of our products has been strictly checked and won the hearts of users. The company insists on developing new technologies, developing a circular economy, and taking the road of high technology and high efficiency. We always regard customer trust as the driving force for the company. You are welcome to give us suggestions or comments.